Demonstration plant Wet steam turbine (WST) in Ronneby - Sörbyverket

Ronneby Miljö & Teknik AB is a municipal company that is wholly owned by the municipality of Ronneby. Their goal is to combine environmental responsibility with economic efficiency.

Ronneby Miljö & Teknik AB is a municipally owned company, which is wholly-owned by the municipality of Ronneby. They manage power, heat, water, sewage, garbage collection, fiber optic networks and broadband. Sörbyverket, the regional district heating plant, is operated by the subsidiary company, Ronneby Miljöteknik Energi AB.

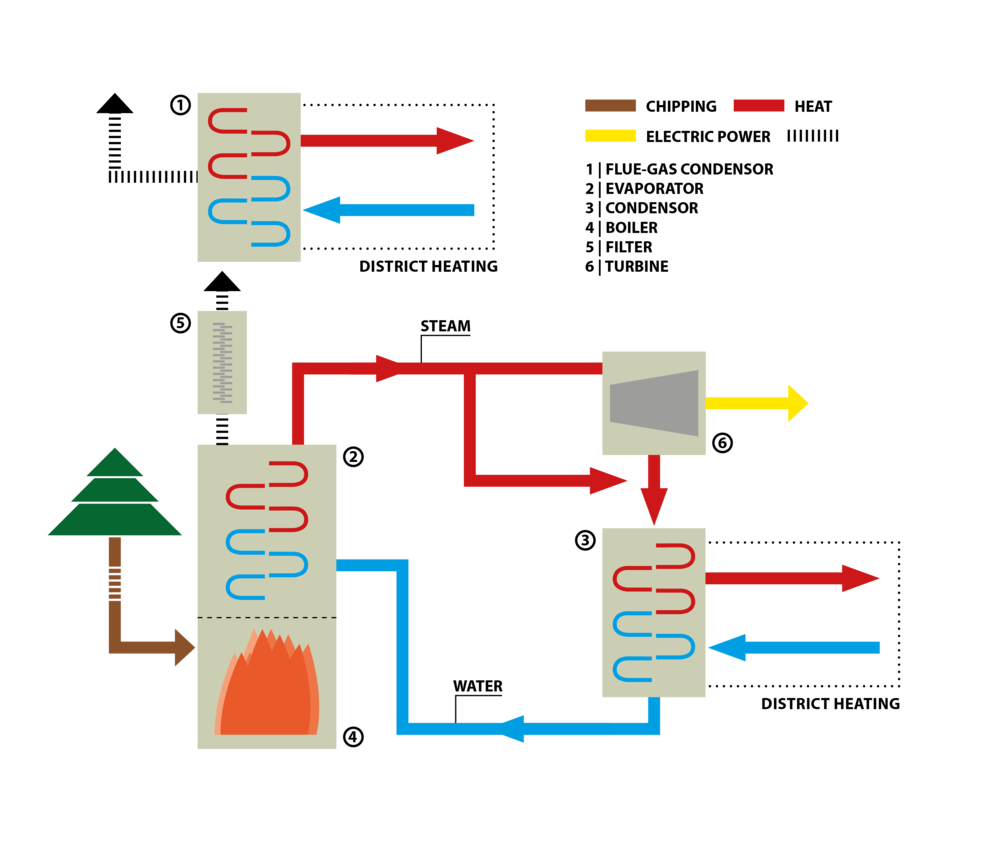

Sörbyverket in Ronneby has built a plant for wet steam, a steam turbine for electricity production at an existing district heating plant

Compared to ordinary steam turbines, a wet steam turbine (WST) can operate at lower pressures and temperatures, with saturated steam. The wet steam turbine is a more robust but not as efficient as conventional turbines. But unlike them, the WST can handle some water particles.

The wet steam turbine is based on the same principle as a conventional steam turbine, which means that it needs to be cooled to condense and release heat. Although the WST does not need to have superheated steam, the boiler needs to produce steam and if a wet turbine is installed in an existing plant, it is most economically advantageous if the boiler is already equipped with a steam turbine. The electrical efficiency of a wet steam turbine is up to about 15%.

Lessons learned

To install a new technology in an old system and get the technologies to communicate and to function optimally can be difficult, especially if the supplier of the turbine focuses on generating as much electricity as possible without taking the entire system into account.

For a wet steam turbine to function optimally and with the best system efficiency for district heating deliveries, the conclusion is that a turbine that requires as much intervention in an existing plant as a wet steam turbine does, should work best if the entire system is adapted from the beginning.

The demonstration of the wet steam turbine had initial problems due to a design error, but when they were solved, the availability of the turbine was high. It would therefore be interesting to test a wet steam turbine on the same scale in a new construction of a combined heat and power plant to be able to evaluate the plant from that perspective.

Download the fact sheet (2020)

WST plant data

EFFECT

500 kW of electricity

ELECTRICITY

Approximately 2 450 MWh / year

THE ESTIMATED PAYBACK

Approximately 17 years (if 4900 hours) 10 years (if 8000 hours)

MOISTURE IN RAW MATERIAL

35-50%

OPERATING HOURS/YEAR

Approximately 4 900 hours

INVESTMENT COST

Approximately 16.8 million

RAW MATERIAL

Wood chips, forest residues, bark, etc.

MODEL

M+M Mini-Turbine

Wet steam turbine manufacturers

Opcon Energy System Opcon Energy SystemSwedish company developing technique for small scale power production from waste heat. The systems are based on their own screw compressor technology using saturated or superheated steam. If the existing boiler does not produce any steam, a flash-tank sold by the company can make the steam required by the turbine. One Swedish reference site is a company using wet steam in their industrial process, although with a very varying demand. By installing a wet steam turbine, they can have a continuous steam production, thereby optimizing their operation, lowering their maintenance costs, and producing their own power as well as heat, that can be sold to a district heating system. |

M+M Turbinen-Technik M+M Turbinen-TechnikGerman company designing and manufacturing customized turbines for several different applications. Their line of production includes a mini turbine. Delivers complete installations, from turbine to generator, including associated control equipment. In Sweden there is a reference site owned by a municipal district heating company, that has installed a turbine with an output far greater than the one at Sörbyverket. |

Siemens Turbomachinery Equipment (formerly KK&K - Kuhnle, Kopp & Kausch) Siemens Turbomachinery Equipment (formerly KK&K - Kuhnle, Kopp & Kausch)Global German company, which among other things develops different types of turbines, including biomass applications. It also delivers complete installations inclusive of generator and control system. Reference site in Sweden that mainly uses biomass in a combined heat and power plant with an output far exceeding the one in Ronneby. |

News about the WST in Ronneby

Information about small scale chp technologies on the Svebio conference

Information about small scale chp technologies on the Svebio conference

2017-11-16

14- 15 of November, project manager Daniella Johansson participated on the Svebio grand biopower and heat conference in Sandviken. The conference began with a study visit to one of the biggest bio power plants in Sweden, co-owned by BillerudKorsnäs and Gävle Energi.

During the conference many topics were discussed, among them the latest news of the climate negotiations in the EU regarding solid biomass and the pellets market in Sweden.

During the second day of the conference, Daniella Johansson moderated a discussion of small-scale cogeneration. A new study on the potential for small-scale cogeneration and various suppliers with new technologies was presented.

The WST in place

2016-10-24

Last week, the turbine was put inside Sörbyverket. The opening of the new wet turbine is scheduled for autumn of 2017.

WST delivery in October

2016-08-26

Sörbyverket will soon be ready for electricity production. Most preparations are made for the delivery of the WST in October.

|

|

Investment of ORC in BräkneHoby

2016-06-29

Ronneby Miljö & Teknik AB is planning for an Organic Rankine Cycle in a thermal power station in BräkneHoby. The procurement of the ORC is currently in process.

Exhibition on Ronneby Energy and Environmental Fair

2016-04-27

Project leader Daniella Johansson talked about Small Scale CHP Life+ and local demonstration plant on Ronneby Energy and Environmental Fair.

Plants for small-scale Combined Heat and Power production are built in Southeast Sweden for demonstration of techniques. Project runs from July 2014–December 2019.

Partners: Emå dairy and Ronneby Miljö & Teknik AB with support from EU financial instrument Life+, Swedish Energy Agency and Energiföretagen Sverige.

|

|

|